With the development of Internet, cloud and big data technology, the application of industrial Internet of things has come to us. More and more industrial automation equipment will need to be connected to achieve data acquisition and analysis; It will explore more equipments value for customers, improve efficiency, reduce cost, optimize management, and promote intelligent transformation of the equipment.

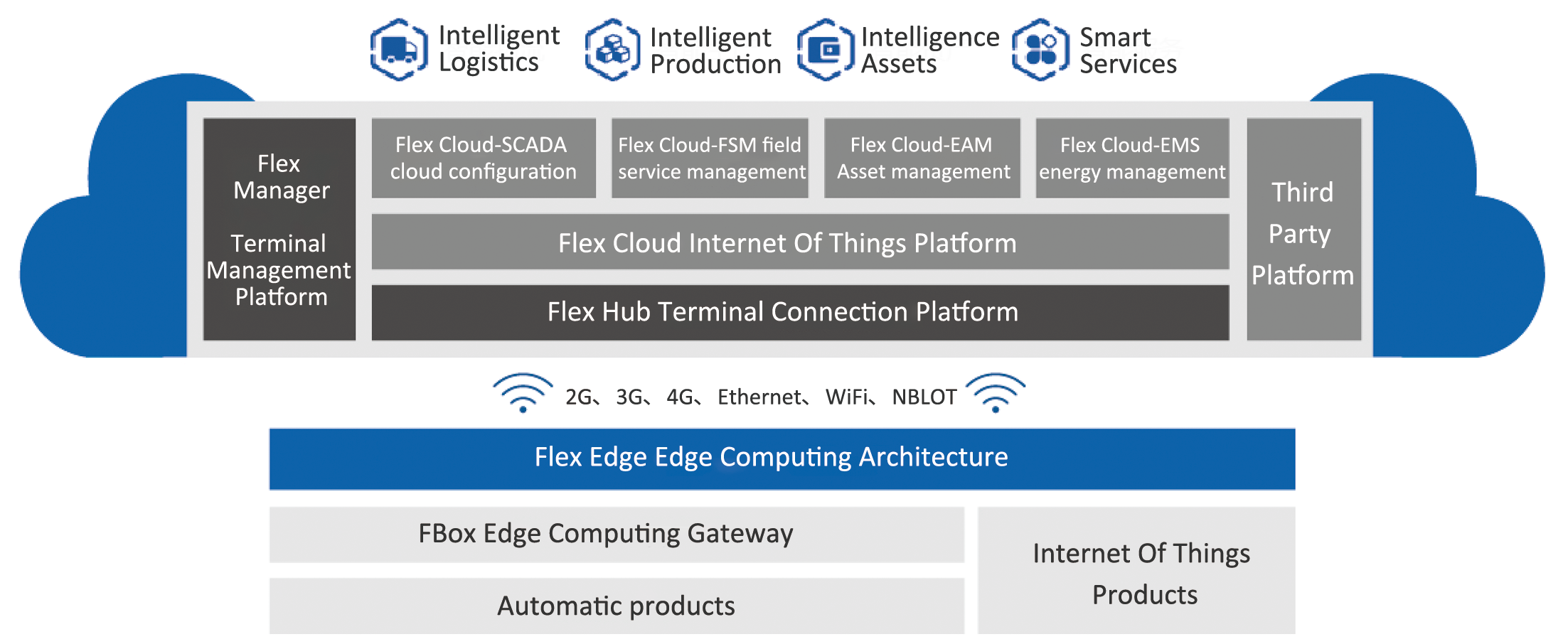

The Industrial Internet of Things has three layers

Data acquisition layer

Data acquisition layer

Internet of things terminal product,edge computing platform FlexEdge

![]() The connection layer

The connection layer

Terminal connection platform FlexHub Terminal cloud management platform FlexManager

The platform layer

The platform layer

Internet of things platform FlexCloud FlexCloud-SCADA, FlexCloud-Fsm

Solution Structure

Internet of things function

Remote pass through PLC program

Remote pass through PLC program

To realize remote PLC program download, upload and monitoring, which can solve the field problems remotely.

Data remote monitoring

Data remote monitoring

The device data can be monitored through web pages or mobile APP, and the running state of the device and parameters can be known and modified in the first time.

Device alarm push

Device alarm push

Through SMS, WeChat, voice and other ways, the failure state of the device can be pushed in the first time to grasp the running state of the device.

Historical data query

Historical data query

It can query the saved historical data and devices data. It also can display it in curve or table form, the meantime export to local position.

Data statistics and analysis

Data statistics and analysis

The energy consumption data and failure rate of the equipment can be counted. The effective assessment and statistics can be carried out for the equipment, which is convenient for different departments such as research and development, after-sales service and sales to conduct analysis.

Improve after-sales service efficiency

Improve after-sales service efficiency

The Internet of things platform can improve the efficiency of after-sales service

Manipulation of the interface

WeChat Scan